News

Dynabrade has partnered with Renny Doyle of Detailing Success to bring you an all-new dual-action polisher that cuts like a rotary and finishes like a DA. Dynabrade is excited about this partnership and the innovation it brings to our tool lineup.

Dynabrade’s new aluminum housing extension die grinders are built for tight spaces and deep channels. Featuring a featherable trigger, durable anodized aluminum body, and low-noise exhaust, these tools are ideal for aerospace, metalworking, and more—lightweight, precise, and ergonomic.

Dynabrade promotes safe tool use with key tips: avoid overinflating wheels, use correct-size pads, respect MOS ratings, and always use guards when required. Lubricate air tools with proper oil, and choose the right dust collection method. Follow ANSI, OSHA, and ISO standards for safety.

HEPA stands for High Efficiency Particulate Air filter, removing 99.97% of particles as small as 0.3 microns. Dynabrade uses medical-grade HEPA (H13–H14) in all vacuums to ensure cleaner air, safer workspaces, and prevent recirculation of harmful dust.

If your Dynabrade sanding pad is worn or damaged, replace it using the included wrench. Always disconnect the air supply first. Dynabrade pads are made in the USA, weight-mated for smooth performance, and tested for durability and safety—ensuring top-quality, swirl-free finishes.

Dynabrade vacuum systems are Class II rated, ideal for collecting combustible dusts. M-Class suits general areas, while Division 1 handles metallic dusts (explosive risk), and Division 2 is for non-metallic dusts. Choosing the right system depends on the dust type and hazard level.

Dynabrade's dust collection systems improve air quality, reduce abrasive use, cut rework, and lower cleaning costs—saving up to $9,787.50 per worker annually. They also support OSHA compliance, protect equipment, and promote a healthier, safer workplace.

Dynabrade has over 30 years of experience making pneumatic sanders. The Supreme, Spirit, and Extreme lines offer options for different needs: Supreme for heavy-duty flat work, Spirit for light vertical use, and Extreme for high-power sanding with top speed consistency.

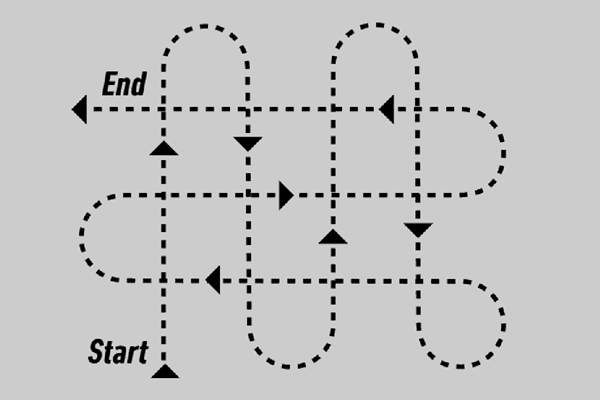

To achieve a swirl-free finish, use the correct random orbital sander, pad, and abrasive. Maintain 90 PSIG air pressure, avoid heavy pressure, and follow a consistent sanding pattern. Keep the sander flat, inspect abrasives often, and clean between grit changes for best results.

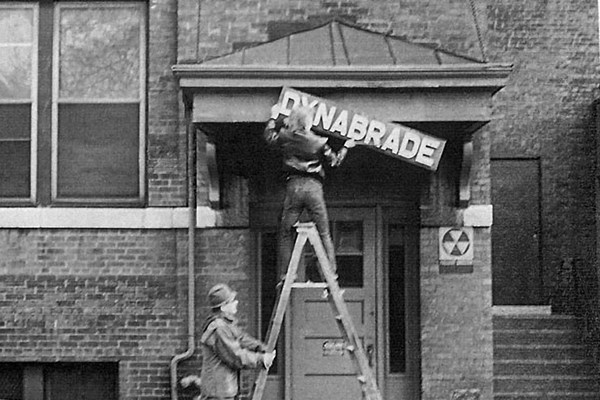

Dynabrade was founded in 1969 by Walter Welsch with the creation of the Dynafile®. The name combines "Dyna" (power) and "abrade" (to wear away), meaning "powered abrasive." Today, Dynabrade is a global leader in high-quality, ergonomic abrasive tools and innovative solutions.

Choosing the right air compressor depends on tool usage, SCFM needs, and pressure. Use two-stage compressors for continuous use. Add 20% to your SCFM total, then divide by 4 or 5 to estimate horsepower. Bigger tanks are better. Need help? Dynabrade reps can assist with sizing.

Dynabrade offers a full range of abrasives for various materials and applications, including silicon carbide, aluminum oxide, zirconia, and ceramic. Options include coated, bonded, and specialty abrasives like carbide burrs and non-woven wheels—ideal for many tools and industries.

Air tools are lighter, more durable, and better for long, demanding jobs. They're safer with water, have less vibration, and last longer with maintenance. Electric tools suit short tasks or side projects. Choose based on job duration, space, and work environment.

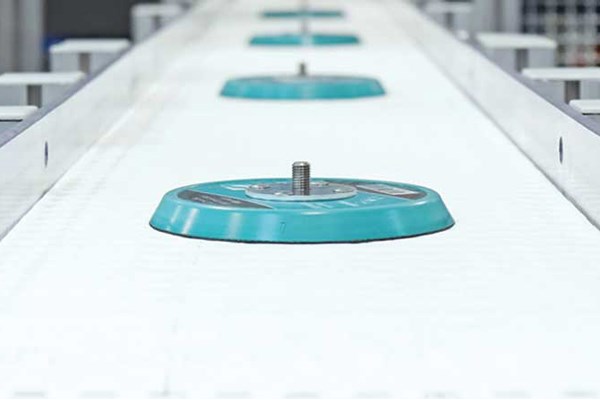

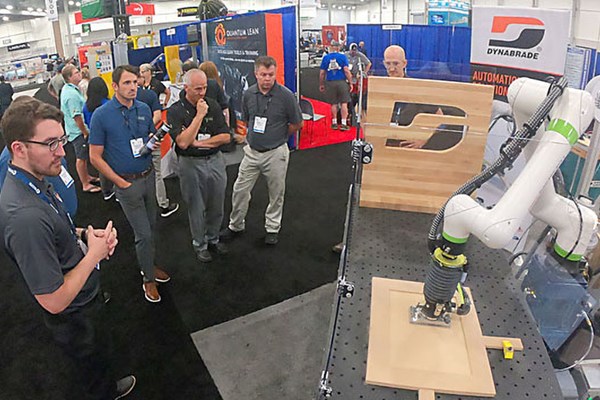

Dynabrade offers 40+ cobot-compatible tools designed for easy attachment and safer, more efficient work. With tool changers and flanges, they adapt to any cobot. Cobots are compact, easy to program, and ideal for repetitive tasks. Dynabrade also provides proof-of-concept support.